Almirah Making Machines

TL Pathak Leading Manufacturer in India

Steel Almirah Making Machine Manufacturer in India

Step into the world of precision engineering and innovation with

TL Pathak Almirah Making Machines.

Manufacturing Process of

Almirah Making Machines

When it comes to manufacturing Almirah Making Machines, TL Pathak Group stands out for its precision and expertise. The process begins with sourcing high-quality raw materials like steel and aluminum to ensure durability and longevity of the machines. Next, skilled technicians use state-of-the-art machinery to cut, shape, and weld the components together with meticulous attention to detail. Each part is carefully inspected for quality control before assembly. The assembly stage involves putting together all the individual components to create a fully functional Almirah Making Machine.

This requires specialized knowledge and experience to ensure everything fits perfectly. Rigorous testing is conducted to guarantee that each machine meets TL Pathak's strict standards for performance and reliability. Only after passing these tests are the machines ready for delivery to their customers. TL Pathak Group's commitment to excellence in every step of the manufacturing process sets them apart as a leader in producing top-notch Almirah Making Machines.

Advantages of using TL Pathak Almirah Making Machine

When it comes to almirah making machines, the TL Pathak Group stands out for its numerous advantages. One key benefit of using TL Pathak Almirah Making Machines is their high efficiency and precision in manufacturing metal components. This results in minimal wastage of materials, ultimately saving costs for manufacturers. Moreover, TL Pathak machines are known for their durability and reliability, ensuring a longer lifespan and consistent performance over time. This means less downtime for maintenance and repairs, leading to increased productivity for businesses.

Additionally, the user-friendly interface of TL Pathak Almirah Making Machines makes them easy to operate even for those new to the industry. The intuitive design allows operators to quickly learn how to use the machines effectively, reducing training time and increasing overall efficiency.

Choosing TL Pathak as your almirah making machine manufacturer can significantly improve your production processes and boost your business's competitiveness in the market.

Top Features of TL Pathak Almirah Making Machine

When it comes to the top features of TL Pathak Almirah Making Machine, quality craftsmanship stands out as a key component. These machines are built with precision and attention to detail, ensuring that every almirah produced is of the highest standard. Another standout feature is the efficiency of TL Pathak machines. With advanced technology and streamlined processes, these machines can produce almirahs at a rapid pace without compromising on quality.

Durability is also a highlight of TL Pathak Almirah Making Machine. The robust construction and high-quality materials used in these machines ensure longevity and reliability, making them a smart investment for any manufacturing business. Additionally, user-friendly interfaces and easy maintenance make operating these machines hassle-free for manufacturers. This ensures smooth production processes and minimizes downtime. The top features of TL Pathak Almirah Making Machine reflect their commitment to excellence in manufacturing equipment.

Steel Almirah that can be Made with

Fully Automatic High Precision Machines

TL Pathak Group's fully automatic high precision machines are versatile and capable of manufacturing a wide range of steel almirahs to meet various needs. With the CNC Fiber Laser Cutting Machine, intricate designs and patterns can be effortlessly cut into the steel sheets for a modern and stylish look.

The NC Shearing Machine ensures precise cutting and shaping of the metal sheets, allowing for seamless assembly of durable and functional steel wardrobes. The UV Printing Machine adds a touch of customization by printing vibrant colors or sleek textures onto the almirah surfaces, making them stand out in any space.

From traditional to contemporary designs, TL Pathak Group's machines can produce single-door, double-door, sliding door, or even designer steel almirah with ease. Whether it's for residential use or commercial spaces, these high-tech machines guarantee top-notch quality and efficiency in manufacturing diverse styles of steel storage solutions.

Advancements in Technology and Future Innovations by TL Pathak Group

TL Pathak Group is at the forefront of technological advancements in manufacturing high precision machines for making steel almirah. Their commitment to innovation has led to the development of cutting-edge CNC Hydraulic Brake Machine, NC Shearing Machine, CNC Fiber Laser Cutting Machine, UV Printing Machine, Mig Welding Machine, Spot Welding Machine, and Pillar Drill Machine. The group continuously invests in research and development to stay ahead of the curve. By incorporating state-of-the-art technology into their machines, TL Pathak Group ensures efficiency and accuracy in every step of the manufacturing process. These advancements not only streamline production but also enhance the quality of steel almirah produced.

Looking towards the future, TL Pathak Group is dedicated to pushing boundaries and exploring new possibilities in machine design and functionality. With a focus on sustainability and customer satisfaction, they aim to revolutionize the industry with innovative solutions that meet evolving market demands.

Process of

Fully Automatic High Precision Machines.

Raw Material

Sheets of Varying thickness are purchased from the market.

Cutting Sheets

Sheets are cut to the require length with the help of Shearing Machine.

Shearing CNC Laser Cutting

After Shearing CNC Laser Cutting is used to make the needs cuts and grooves as per the almirah design.

Uses of Press Brake Machine

After these 2 opeation the accurately cut sheets are bended at 90 degrees or other required angles with the help of Press Brake Machine.

Welding

Mig Welding / Spot Weldings are used to weld the almirah and its parts together.

Accessories

Require locks / hinged / other accessories such as glas etc are installed as per the almirah model.

Finishing

Now after doing surface treatment of the finished almirah.

Printing

The UV Printer is used to print any type of pictures or design on the almirah top (this piece is assmbled last).

Overview of

Semi Automatic Almirah Making Machine

With its semi-automatic functionality, this machine offers a perfect balance between manual control and automated features. It allows operators to have hands-on involvement in the production process while also benefiting from advanced technology.

The Semi Automatic Almirah Making Machine boasts a user-friendly interface, making it easy for operators to learn and operate efficiently. Its innovative design enables seamless integration into existing production lines, minimizing downtime and maximizing output. Experience increased productivity, improved accuracy, and cost savings with this state-of-the-art machine. Say goodbye to traditional methods of almirah manufacturing and embrace the future with TL Pathak's Semi Automatic Almirah Making Machine!

Key Features and Benefits of the Machine

When it comes to the Semi Automatic Almirah Making Machine by TL Pathak Manufacturer, there are several key features that set it apart from the rest. First and foremost, this machine is equipped with advanced hydraulic press brake technology, ensuring precise bending of metal sheets for almirah production. The under crank shearing mechanism allows for clean and accurate cutting of materials, enhancing efficiency in the manufacturing process.

Moreover, the stand spot welding capability ensures strong and durable welds on almirah components, guaranteeing long-lasting quality. The addition of hand spot welding functionality provides flexibility for intricate welding tasks.

Additionally, the power press machine incorporated into this system offers high-speed operation and increased productivity. With these innovative features combined, businesses can experience improved workflow and higher output levels when producing almirah using this semi-automatic machine.

Process of

Semi Automatic Almirah Making.

Raw Material

Sheets of varying thickness are purchased from the market.

Cutting Sheets

Sheets are cut to the require length with the help of Shearing Machine.

Shearing CNC Laser Cutting

After shearing Power Press Machine is used to make the needed cuts and grooves as per the almirah design.

Uses of Press Brake Machine

After these 2 operation the accurately cut sheets are bended at 90 degrees or other required angles with the help of Press Brake Machine.

Welding

Mig Welding / Spot Welding’s are used to weld the almirah and its parts together.

Accessories

Required locks / hinged / other accessories such as glass etc are installed as per the almirah Model.

Finishing

Now after doing surface treatment of the finished almirah.

Power Coating

Power coating process is used to paint the almirahs.

Overview of

Manual Machines for Steel Almirah Making

When it comes to making steel almirahs, using manual machines offers several key benefits. One advantage is the cost-effectiveness of these machines compared to automated options. Manual machines are often more affordable, making them a great choice for small businesses or workshops with budget constraints.

Additionally, manual machines give operators more control and precision over the manufacturing process. This hands-on approach allows craftsmen to tailor each piece according to specific requirements, resulting in unique and customized steel almirahs.

Another benefit of using manual machines is their versatility. These machines can handle various tasks such as bending, shearing, drilling, and pressing – providing a comprehensive solution for steel almirah production needs. Moreover, manual machines are known for their durability and reliability. They require minimal maintenance and have a longer lifespan compared to automated machinery – ensuring long-term efficiency and performance in your workshop.

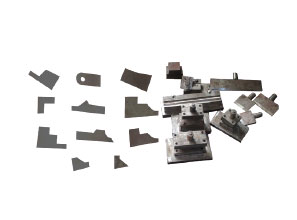

Different Types of Manual Machines Offered by TL Pathak Manufacturer

TL Pathak Manufacturer offers a variety of manual machines for steel almirah making to meet different production needs.

One of their popular machines is the manual press brake machine, designed for bending and shaping metal sheets with precision. It allows for accurate results in creating complex bends. Another essential tool provided by TL Pathak is the manual sheet folding machine, which enables seamless folding of metal sheets to create sturdy components for steel almirahs.

For tasks requiring precise compacting of materials, the manual ball press machine by TL Pathak proves to be efficient and reliable. With adjustable pressure settings, it ensures consistent results every time. In addition, their hand lever type shearing machines are ideal for cutting through various thicknesses of metal sheets quickly and effortlessly. TL Pathak also offers bench drill machines that provide high drilling accuracy for creating holes in steel components effectively.

Process of

Fully Automatic High Precision Machines.

Raw Material

Sheets of varying thickness are purchased from the market.

Cutting Sheets

Sheets are cut to the require length with the help of Hand Shearing Machine.

Shearing Manual Press Machine

After Shearing Manual Press Machine is used to make the needed cuts and grooves as per the almirah design.

Uses of Manual Press Brake Machine

After these 2 operation the accurately cut sheets are bended at 90 degrees or other required angles with the help of Screw Type Manual Press Brake Machine.

Welding

ARC / Mig Welding / Spot Welding’s are used to weld the almirah and its parts together.

Accessories

Required locks / hinged / other accessories such as glass etc are installed as per the almirah model.

Air Compressor

Air Compressor is used to spary paint the Almirah.

Future of Almirah Making Industry in India

The future of the Almirah making industry in India looks promising as

the demand for quality storage solutions continues to rise.

With rapid urbanization and increasing disposable income, more households and businesses are seeking durable and stylish almirahs. As technology advances, we can expect to see innovative features integrated into almirah making machines. Automation and digitalization will streamline production processes, leading to higher efficiency and lower costs. This will ultimately benefit manufacturers by enabling them to meet consumer demands more effectively.

Furthermore, sustainability is becoming a key focus in manufacturing industries worldwide, including the Almirah making sector. Companies that prioritize eco-friendly practices and materials will likely gain a competitive edge in the market. With evolving consumer preferences and technological advancements shaping the industry's trajectory, it is safe to say that the future of Almirah making in India holds immense potential for growth and innovation.