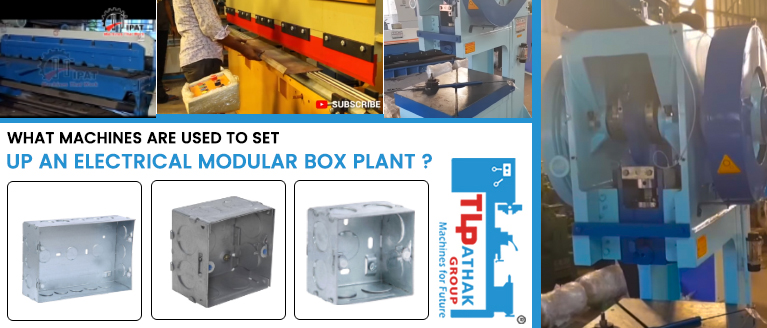

What machines are used to set up an Electrical Modular Box Plant

Published On: Jun 24, 2024 by Pathak

Attention all aspiring entrepreneurs and industry professionals! Are you ready to revolutionize the electrical modular box manufacturing industry. From the humble light switch to the complex circuit panels that power our homes and businesses, electrical modular boxes are essential components of modern infrastructure. But have you ever wondered what goes into setting up a plant to manufacture these vital pieces of equipment

Why are machines important for setting up a plant?

Setting up an Electrical Modular Box Plant requires a range of machines to streamline production processes and ensure high-quality output. These machines play a crucial role in enhancing efficiency, accuracy, and productivity within the plant. Investing in cutting and bending machines enables precise shaping of sheet metal for box components. Punching and notching machines help create accurate holes and slots for mounting electrical components. Welding machines are essential for joining metal parts securely together. Painting and coating machines provide a protective finish while maintaining aesthetic appeal. Testing and quality control machines ensure that all products meet industry standards before they reach the market. In essence, having the appropriate machinery is vital for establishing a successful Electrical Modular Box Plant that can meet customer demands efficiently and effectively.

Types of machines needed for an Electrical Modular Box Plant

Punching Machines are also vital for creating precise holes and cutouts in the metal sheets used for modular boxes. These machines ensure that all components fit together seamlessly during assembly. Welding Machines play a key role in joining different parts of the modular boxes securely. Spot Welding Machines, in particular, provide quick and efficient bonding of metal sheets without compromising on strength. Painting and Coating Machines are important for adding a protective layer to the modular box components, enhancing their durability against environmental factors like corrosion. Lastly, Testing and Quality Control Machines are necessary to ensure that each component meets industry standards before being assembled into final products. These machines help maintain consistency in quality throughout the manufacturing process.

Mechanical Power Press

The Mechanical Power Press is a powerful and precise machine that plays a crucial role in the manufacturing of Electrical Modular Box Plants. With its sturdy frame and robust components, the Mechanical Power Press delivers controlled force to shape and cut through various materials with ease. Its versatile capabilities allow for intricate designs to be stamped out effortlessly, ensuring uniformity and precision in each component of the box plant. The reliability and efficiency of the Mechanical Power Press make it an indispensable tool in streamlining production processes, enabling manufacturers to meet deadlines with exceptional quality. Whether punching holes or forming complex shapes, this powerhouse machine showcases unmatched strength and accuracy in transforming raw materials into functional electrical modular boxes.

Sheet Shearing Machine

The Sheet Shearing Machine is an essential tool in the manufacturing process of Electrical Modular Box plants. This powerful machine is designed to precisely cut through metal sheets with incredible speed and accuracy, ensuring that each piece is perfectly sized for assembling the modular boxes. With its sharp blades and strong motor, the Sheet Shearing Machine can effortlessly slice through a variety of materials, including steel and aluminum, making it versatile enough to handle any project requirements. Its user-friendly interface allows operators to easily adjust settings and customize cuts to meet specific design specifications. Thanks to its efficient performance and reliable results, the Sheet Shearing Machine plays a crucial role in streamlining production processes and delivering high-quality electrical modular box products to customers around the world.

Power Press Brake

The Power Press Brake machine is an essential tool in the manufacturing process of electrical modular box plants. This powerful machine utilizes hydraulic force to bend and shape metal sheets with precision and accuracy, ensuring that each piece fits perfectly into the final product. With its robust design and advanced technology, the Power Press Brake can easily handle even the thickest and toughest materials, making it ideal for producing durable and reliable electrical boxes. Its user-friendly controls allow operators to adjust settings quickly and efficiently, resulting in a seamless production line that meets strict quality standards. Whether crafting intricate components or large-scale panels, the Power Press Brake delivers exceptional results every time, making it indispensable in the creation of top-notch electrical modular box plants.

Welding machines come in various types and sizes to cater to different needs within the plant. From spot welding machines for precise connections to power brake machines for bending and shaping metal sheets, each type serves a specific purpose in the production line. The quality of welds produced by these machines is vital for ensuring the durability and reliability of the electrical modular boxes manufactured. Manufacturers need to invest in high-quality welding equipment that can deliver consistent results with minimal room for error. Spot Welding Machines offer precise control over the welding process, allowing operators to create strong bonds between metal sheets without causing damage or distortion. Power Brake Machines provide versatility in bending metal sheets according to specific requirements, ensuring seamless integration into final products.

Testing and Quality Control Machines

These machines are designed to check for any defects or inconsistencies in the electrical modular boxes before they are released into the market. They help identify any issues early on, preventing faulty products from reaching customers and ultimately protecting your brand reputation. From conducting electrical tests to checking dimensions and ensuring proper assembly, testing and quality control machines provide that extra layer of assurance that your products meet industry standards. By investing in these machines, you can uphold quality control measures and deliver reliable products to your customers every time.

Features to look for when purchasing machines

Durability and reliability are essential factors to look for in machinery. Investing in high-quality equipment that can withstand the demands of daily use will ensure longevity and minimize downtime. Speed and efficiency play a significant role in maximizing productivity. Opting for machines that can perform tasks quickly and accurately will help streamline production processes and meet deadlines effectively. Consider the size and compatibility of the machines with your plant layout. Ensure that the equipment fits well within your space constraints and integrates seamlessly into your existing workflow. By prioritizing these features when selecting machines for your Electrical Modular Box Plant, you can set up a highly efficient manufacturing facility equipped to meet industry standards effortlessly.

Durability and reliability

Investing in durable machines ensures that they can withstand the demands of a manufacturing environment over the long term. Look for machines made from high-quality materials that are built to last through continuous use. Reliability is equally important as it minimizes downtime and keeps production running smoothly. Choose machines from reputable manufacturers known for their dependable products.

By prioritizing durability and reliability in your machine selection process, you are making a sound investment in the future success of your plant.

Speed and efficiency Having machines that can operate quickly and efficiently can significantly impact the productivity of your plant. Time is money in any manufacturing business, so having machines that can perform tasks swiftly without compromising quality is crucial. Look for machines with high-speed capabilities that can handle a large volume of work within a short period. Efficiency goes hand in hand with speed – you want machines that not only work fast but also deliver accurate results consistently. Investing in equipment that maximizes both speed and efficiency will help streamline your production process and improve overall output. By prioritizing these qualities when selecting machinery for your Electrical Modular Box Plant, you are setting yourself up for success in the competitive manufacturing industry.

TL Pathak can assist you in setting up an electrical modular box plant in India

TL Pathak, a experienced industry expert with 50 years of experience in the electrical manufacturing sector, can be your guiding light in establishing an innovative and efficient electrical modular box plant in India. His meticulous attention to detail and extensive knowledge of the market ensure that every aspect of the project is handled with precision and care. From selecting the perfect location for your plant to designing a layout that maximizes efficiency, TL Pathak will guide you through each step of the process. With his guidance, you can rest assured that your electrical modular box plant will be set up to meet all quality standards and regulations. Trust TL Pathak to turn your vision into reality and lead you towards success in this venture.

========================================================================================================

इलेक्ट्रिक मॉड्यूलर बॉक्स बनाने के व्यवसाय की जानकारी हिंदी में प्राप्त करने के लिए यहां क्लिक करें।

========================================================================================================

Lastest Articles

-

Embracing NC Hydraulic Press Brake Technology in Middle East Factories

Being a prominent center for indust... -

What machines are used to set up an Electrical Modular Box Plant

Attention all aspiring entrepreneur... -

Manual Process For Making Steel Almirah

Steel almirah are not only durable ... -

Semi Automatic Almirah Making Machines

Streamlining Production Processes w... -

Steel Almirah Manufacturing With Fully Automatic High Precision Machines

Welcome to the world of precision a... -

Unlocking the Power of Precision Understanding the Purpose and Functionality of Drilling Machines

A drilling machine is a tool used f... -

A Beginners Guide to C-Frame Presses for Industrial Applications

Welcome to the world of C-frame pre... -

Busbar Machine Applications in Automotive Manufacturing

Busbar Machine Applications i... -

How Busbar Machines Contribute to Electrical Safety and Reliability

How Busbar Machines Contribute to E... -

A Beginner's Guide to Busbar Fabrication and Assembly

A Beginner's Guide to Busbar Fabric...