Door Fittings Making Machines

Door Fittings Making Machines

Streamline Your Door Fittings Production with

Our High Quality Machinery

Sheet metal processing machines made by TL Pathak are used to manufacture

Door and Window fitting products

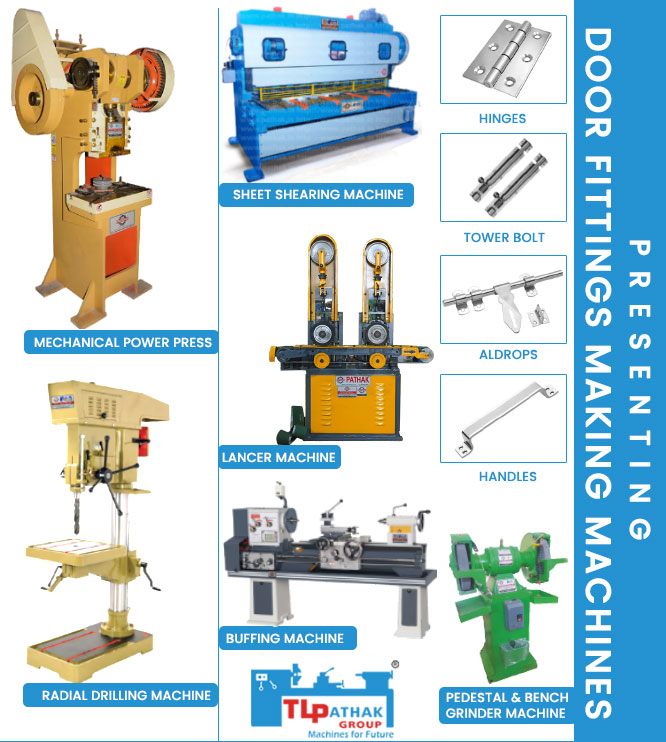

The innovative Sheet metal processing machines manufactured by TL Pathak play a crucial role in the production of high-quality door fittings. The Sheet Shearing Machine ensures precise cutting of the metal sheets, allowing for perfect dimensions required for handles, hinges, tower bolts, and aldrops. The Mechanical Power Press is utilized to punch holes or create intricate designs on the metal surfaces with impeccable accuracy.

The Radial Drilling Machine enables the drilling of holes in various sizes and positions on the fittings, ensuring proper alignment and functionality once installed on doors. Lastly, the Buffing Machine adds a flawless finish to the door fittings, enhancing their aesthetic appeal and durability. With these state-of-the-art machines from TL Pathak at work, manufacturing top-notch door fittings has never been easier or more efficient.

Sheet Shearing Machine

The initial step in producing a sheet metal component involves cutting it to the appropriate size. This task can be accomplished by various types of shearing equipment, which are versatile machines designed for cutting alloys and other types of sheet metal. Some shearing machines work with an angular shear motion similar to scissors, while larger ones utilize a straight shear action with a fixed angled blade. In either case, the process involves two blades - one stationary and one moving up and down with little clearance between them. As the shearing action progresses from one side of the material to the other, the rake (the angle of the blades) and clearance (the space between them) play significant roles in achieving the desired outcome. In press type shears, for example, the upper blade is typically tilted at an angle of .5 to 2.5 degrees relative to the lower blade. The machine itself usually consists of a stable base, one mounted blade, a vertically moving crosshead, and hold-down mechanisms such as pins or feet that keep the material in place during cutting. To ensure precise workpiece dimensions, a gauging system equipped with stops is employed.

Sheet Sheaing Machine

Specification

| Model | Cutting Cap. in MS Length-X Thickness | Stroke Per Minute | Table Height | Table Width | Front Gauge | Rear Gauge | Motor HP/WK | Blade Length X Width X Thickness | Overall Dimension in M.M | ||

| Length A | Width B | Height C | |||||||||

| POS-156 | 1525X6 | 25 | 750 | 450 | 600 | 750 | 7.5/5.5 | 1525X75X18 | 2500 | 1950 | 2300 |

| POS-206 | 2030X6 | 25 | 750 | 450 | 600 | 750 | 10/7.7 | 2030X75X18 | 2300 | 1200 | 2500 |

| POS-256 | 2540X6 | 25 | 750 | 450 | 600 | 750 | 10/7.7 | 2540X75X18 | 2800 | 1500 | 2650 |

| POS-185 | 1525X8 | 20 | 750 | 450 | 600 | 750 | 10/7.7 | 1525X75X18 | 3400 | 1575 | 2750 |

| POS-208 | 2030X8 | 20 | 750 | 450 | 600 | 750 | 12.5/9.7 | 2030X75X18 | 2400 | 1575 | 2750 |

| POS-258 | 2540X8 | 20 | 750 | 450 | 600 | 750 | 15./11.2 | 2540X75X22 | 2900 | 1650 | 3025 |

| POS-318 | 3125X8 | 20 | 750 | 450 | 600 | 750 | 20/15 | 3125X75X22 | 3450 | 1875 | 3525 |

| POS-2010 | 2030X10 | 20 | 800 | 450 | 600 | 750 | 15/11.2 | 2030X100X20 | 2900 | 1900 | 3550 |

| POS-2510 | 2540X10 | 20 | 800 | 450 | 600 | 750 | 20/15 | 2540X100X22 | 3400 | 1900 | 3550 |

| POS-3110 | 3125X10 | 20 | 800 | 450 | 600 | 750 | 25/18.7 | 3125X100X25 | 3400 | 1950 | 3650 |

| POS-1513 | 1525X13 | 20 | 800 | 450 | 600 | 750 | 15/11.2 | 1525X100X25 | 3400 | 1575 | 2750 |

| POS-2013 | 2030X13 | 20 | 800 | 450 | 600 | 750 | 20/15 | 2300X100X25 | 1575 | 2750 | 2750 |

| POS-2513 | 2540X13 | 20 | 800 | 450 | 600 | 750 | 25/18.7 | 2540X100X25 | 2900 | 1650 | 3025 |

| POS-2016 | 2030X16 | 20 | 800 | 450 | 600 | 750 | 25/18.7 | 2030X100X25 | 3450 | 1875 | 3525 |

| POS-2516 | 2540X16 | 20 | 800 | 450 | 600 | 750 | 30/22.5 | 2540X100X25 | 2900 | 1900 | 3550 |

| POS-3116 | 3125X16 | 20 | 800 | 450 | 600 | 750 | 40/30 | 3125X100X25 | 3400 | 1900 | 3550 |

Mechanical Power Press

The mechanical power press is a formidable machine in the world of manufacturing, capable of shearing, punching, forming, and assembling metal with precision and efficiency. In the realm of door fittings products making machines, this powerhouse device reigns supreme. With tools or dies attached to slides or rams, it transforms raw materials into functional pieces that are essential for securing doors in place. The process is simple yet complex - stock is carefully placed on a bottom die before being struck with a top die, resulting in seamless metalworking magic. The clanking sound of the press resonates throughout the workshop as it tirelessly churns out perfectly crafted components ready for their next assembly. With its unyielding strength and unwavering accuracy, the mechanical power press stands as a testament to human ingenuity and technological advancement in modern manufacturing processes; truly a marvel to behold.

Mechanical Power Press

Specification (Available in 5 Tons to 200 Tons)

| CAPACITY IN TONS | 5 TONS | 10 TONS | 40 TONS | 50 TONS | 60 TONS | 80 TONS | 100 TONS | 150 TONS | 200 TONS |

| Crankshaft Diameter | 70 | 88 | 135 | 140 | 150 | 160 | 170 | 190 | 250 |

| Adjustment of Stroke | 38 | 50 | 76 | 89 | 100 | 115 | 130 | 150 | 150 |

| Adjustment of Ram | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| 25Punch Hole in Ram | 25 | 25 | 38 | 45 | 45 | 50 | 50 | 80 | 80 |

| Hole in Bed | 63 | 76 | 95 | 101 | 115 | 130 | 150 | 200 | 225 |

| Bed Size (Length x Width) | 355x178 | 432x228 | 635x355 | 685x406 | 712x457 | 738x508 | 891x612 | 1041x737 | 1100x813 |

| Bed Thickness | 50 | 58 | 76 | 83 | 88 | 95 | 114 | 127 | 137 |

| Dist.between bed to Ram | 177 | 204 | 320 | 350 | 380 | 380 | 406 | 457 | 482 |

| Flywheel Dia. | 406 | 458 | 584 | 660 | 762 | 812 | 863 | 965 | 1016 |

| Stroke per minute | 80 | 70 | 35 | 35 | 30 | 30 | 30 | 25 | 25 |

| H.P Required | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| For Geared (1440 RPM) | 1 | 1.5 | 4 | 5 | 7.5 | 10 | 10 | 12.5 | 15 |

| For Ungeared (960 RPM) | 1 | 2 | _ | _ | _ | _ | _ | _ | _ |

| Floor to top of Bed | 700 | 830 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Allover Size LR X FB X H | 700x600x1600 | 800x800x1900 | 1100x1200x2400 | 1200x1300x2500 | 1300x1350x2650 | 1500x1500x2750 | 1750x1750x2900 | 2050x2000x3300 | 2200x2150x3500 |

| Weight Approximate | 350 | 600 | 1900 | 2500 | 2700 | 3200 | 4700 | 6200 | 7700 |

Radial Drilling Machine

The Radial Drilling Machine is a versatile and essential tool for creating precision door fittings products. With its unique design, this special purpose drilling machine features a drilling head that effortlessly glides along the radial arm, allowing for precise adjustments to be made on the vertical pole. Whether it's raising, lowering, or rotating the arm, this machine provides unparalleled control over the positioning of the drill above the workpiece. This level of accuracy ensures that every hole drilled is perfectly aligned and consistent, resulting in high-quality door fittings products that meet even the most stringent standards. The Radial Drilling Machine truly elevates production efficiency and craftsmanship to new heights in manufacturing these essential components.

Radial Drilling Machine

Specification

| Model | PS-40 |

| Titling working table | Fixed |

| Drilling capacity | 40 mm |

| Pilllar diameter | 121 mm |

| Spindle nose to table distance | 595 mm |

| Distance from spindle nose to base distance | 1050 mm |

| Distance from spindle centre to pillar surface (in mm) | 320 (max) |

| Table level | 480 mm |

| Taper in spindle | MT-4 |

| number of speed | 8 speed |

| Range of speed (RPM) | 70 to 2000 |

| Table size (in mm) | 410 x 410 |

| Base size (m/c area in mm) | 440 x 715 |

| Overall base size (in mm) | 445 x 720 |

| Spindle travel | 250 mm |

| Pillar length | 1450 mm |

| Overall height with pulley gurad | 1860 mm |

| V-belt section | B-59 |

| Weight (Approx) | 325 kgs |

| Motor 1440 RPM 3 Phase 440 Volts | 2 H.P |

| Shipping wooden case | 860x460 |

| Inner size LxWxH | 1580 mm |

Buffing Machine

The cast iron used in this product is of superior quality and precisely machined to ensure precise alignment of its bearings. The frame and feet are constructed as a single piece, providing thorough coverage of the motor's working components. Both the stator and rotor cores are made up of thin layers of top-grade silicon steel, each insulated from the other to minimize core losses. Our stator windings are made with high-grade super-enamelled wire, thoroughly dried and coated in insulating varnish for optimal insulation. Additionally, our shafts are crafted from first-rate mild steel, closely machined and expertly ground for precise bearing placement.

Buffing Machine

Specification

| Model Pedestal Type | Model Bench Type | Wheel Size | Motor Rating H.P | N.L.R.P.M |

| PPG-1 | PBG-1 | 6''x1/2''x1/2'' | .5 | 2880 |

| PPG-2 | PBG-2 | 6''x3/4'' TO 1''x1/2'' | .5 | 2880 |

| PPG-6 | PBG-6 | 8''x1''x5/8'' | 1 | 2880 |

| PPG-7 | PBG-7 | 10''x1''x1'' | 1 | 1500 |

| PPG-7A | PBG-7A | 10''x1''x1'' | 1.5 | 3000 |

| PPG-8 | PBG-8 | 10''x1''x1'' | 1.5 | 1500 |

| PPG-9 | PBG-9 | 12''x1.1/2''x1'' | 2 | 1500 |

| PPG-9A | PBG-9A | 12''x2''x1'' | 2 | 1500 |

| PPG-10 | PBG-10 | 14''x1.1/2''x1.1/2'' | 2.5 | 1500 |

| PPG-10A | PBG-10A | 14''x2''x2'' | 3 | 1500 |

| PPG-11 | PBG-11 | 16''x1.1/2''x1.1/2'' | 3 | 1500 |

| PPG-12 | PBG-12 | 16''x2''x2'' | 3 | 1500 |

| KA-50 | ----- | 18''x2''x2'' | 7.5 | 1500 |

| KA-75 | ----- | 18''x3''x2'' | 7.5 | 1500 |

| KA-75A | ----- | 18''x3''x2'' | 7.5 | 1500 |

Hinges Making Machines

Door & Window Handle Making Machines

Door & Window Hinges / Handle Application

Stainless Steel Door Hinges

6 Pack Non Mortise Door Hinges

Door Handle

Window Handle

Lathe Machine

The Lathe Machine is an indispensable tool in the creation of high-quality Door & Window Tower Bolts. With precision and accuracy, this machine ensures that every bolt is crafted to perfection. The sturdy steel material is expertly manipulated by the lathe as it spins and shapes the metal into a sleek and durable design. The sharp cutting tools effortlessly trim away excess material, creating smooth edges that are both aesthetically pleasing and secure for locking doors and windows. Each bolt undergoes meticulous attention to detail on the lathe, from drilling holes for screws to threading grooves for enhanced grip. The result is a finely-crafted Tower Bolt that guarantees safety and security for your home or office spaces. Trust in the power of the Lathe Machine to deliver unmatched quality in every Door & Window Tower Bolt it produces.

Lathe Machine

Specification

| MODEL | PLD 4 G | PLD 6 G |

| Height of Center | 165 | 165 |

| Swing over Bed | 330 | 330 |

| Swing over Slide | 190 | 190 |

| A.B.C. | 600 mm | 1000mm |

| Width of Bed | 242 | 242 |

| SPINDLE | SPINDLE | |

| Bore | 40 | 40 |

| Nose | Thread | Thread |

| Speed-8 R.P.M | 45 to 1000 | 45 to 1000 |

| TRAVEL | TRAVEL | |

| Cross Slide | 180 | 180 |

| Top Slide | 125 | 125 |

| OTHER | OTHER | |

| Lead Screw TPL | 4 | 4 |

| Tail Stock Sleeve Mt | 3 | 3 |

| Power Required (H.P.) | 2 | 2 |

| THREAD | THREAD | |

| Thread Per inch | 4 to 60 | 4 to 60 |

| Thread Per mm | 0.5 to 7.5 | 0.5 to 7.5 |

Tower Bolt Making Machines

Door & Window Tower Bolt Making Machines

Door Tower Bolt Application

Tower Bolts

Tower Bolts

Tower Bolts

Tower Bolts

Hinge Polishing Machine / Lance Machine

The Hinge Polishing Machine is an essential tool in any Door Aldrops Making Machine, capable of effortlessly polishing square bars and pipes, rectangle bars and pipes, square small parts, rectangle small parts, and sheet metal components. Its versatility allows for a wide range of metals to be polished with precision and efficiency, including stainless steel, aluminum, brass, copper, mild steel, and more. This advanced machine ensures a flawless finish on all types of metal materials used in door hardware manufacturing. With its automated features and specialized design for various shapes and sizes of components, the Hinge Polishing Machine guarantees superior quality results every time. Whether working with intricate hinges or durable aldrops for doors, this cutting-edge technology delivers consistent excellence in polishing performance.

Hinge Polishing Machine / Lance Machine

Specification

| Model | PHPM |

| Capacity | 1/2" Square to 3" Square |

| Flap Wheel | 300x50x127 mm |

| Gear Box | Self Made+2 HP Motor |

| Main Head Motor | 3 HP 2800 RPM |

| Feed | Through Feed Roller |

Aldrops Making Machine

Door Aldrops Making Machines

Aldrops Application

Tower Bolts

Tower Bolts

Tower Bolts

Tower Bolts

Invest in Efficient Production

for Long Term Success

Investing in high-quality machinery like our Sheet Shearing Machine, Mechanical Power Press, Radial Drilling Machine, and Buffing Machine is a strategic move to stay ahead of the competition in the door fittings industry. By streamlining your production process with efficient equipment, you can boost productivity, increase efficiency, and ultimately achieve long-term success. Our machinery offers cutting-edge features and benefits that cater specifically to the needs of door fittings manufacturers. From precision cutting to smooth finishing touches, our machines are designed to deliver top-notch results consistently.