Electrical Modular Box Making Machines

Electrical Modular Box Making Machines

TL Pathak provides next generation turnkey solutions for metal processing industries!

Turnkey Solution to Metal Processing Industries

Introduction to

Metal Electrical Modular Boxes

TL Pathak Group revolutionizes the metal processing industry with their cutting-edge Electrical Modular Box Making Machines. These innovative machines are designed to streamline production processes and increase efficiency in manufacturing electrical modular boxes. With TL Pathak's expertise and forward-thinking approach, these machines are equipped with state-of-the-art technology that allows for precise measurements and high-quality output. The group's dedication to providing turnkey solutions sets them apart as leaders in the field, offering comprehensive support from design to installation. Utilizing TL Pathak Group's advanced machinery ensures seamless production of electrical modular boxes, setting a new standard for excellence in the industry..

The Evolution of Manufacturing Processes for Metal Electrical Modular Boxes

Metal electrical modular boxes have come a long way in terms of manufacturing processes. In the past, these boxes were crafted by hand, requiring skilled labor and more time to produce. However, with advancements in technology, machines are now widely used to streamline the manufacturing process.

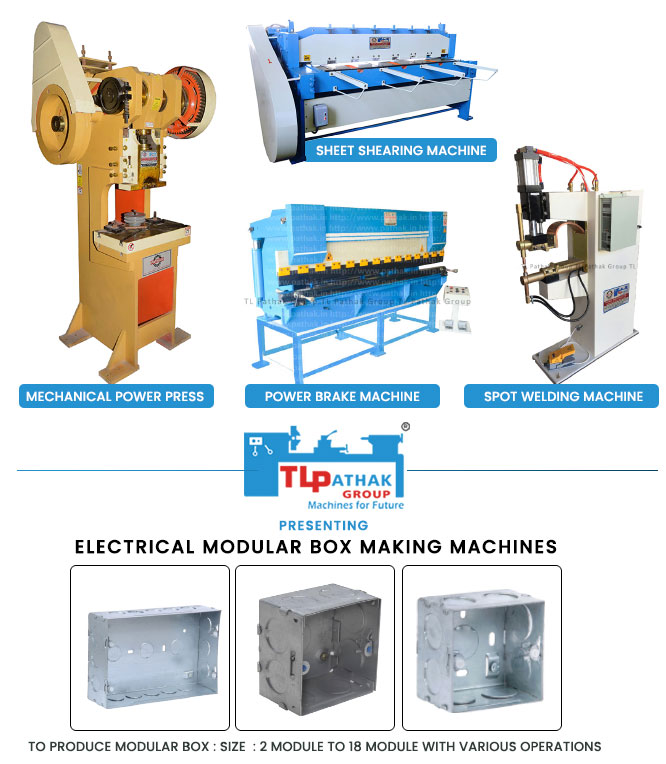

The evolution of manufacturing processes for metal electrical modular boxes has led to increased efficiency and precision. Machines such as mechanical power presses, sheet shearing machines, power brake machines, and spot welding machines play a crucial role in shaping and assembling these boxes with speed and accuracy.

These modern machines have revolutionized the industry by automating tasks that were once done manually. This not only saves time but also ensures consistency in the quality of the final product. As technology continues to advance, we can expect further improvements in the manufacturing processes for metal electrical modular boxes.

The Evolution of Manufacturing Processes for Metal Electrical Modular Boxes

Metal electrical modular boxes have come a long way in terms of manufacturing processes. In the past, these boxes were crafted by hand, requiring skilled labor and more time to produce. However, with advancements in technology, machines are now widely used to streamline the manufacturing process.

The evolution of manufacturing processes for metal electrical modular boxes has led to increased efficiency and precision. Machines such as mechanical power presses, sheet shearing machines, power brake machines, and spot welding machines play a crucial role in shaping and assembling these boxes with speed and accuracy. These modern machines have revolutionized the industry by automating tasks that were once done manually. This not only saves time but also ensures consistency in the quality of the final product. As technology continues to advance, we can expect further improvements in the manufacturing processes for metal electrical modular boxes.

Metal Electrical Modular Box Making Machines

Automatic Plant

- High-quality materials are used in the production of die sets to ensure long-term durability and precise material pressing.

- In order to ensure long-term reliability and stability, presses are often built with heavy-duty frames and reinforced structures.

- Ensures consistent production and minimizes downtime with durable components.

- Featuring energy-efficient technologies, such as motor controls or power-saving features, to reduce energy consumption and save money

- Easy to use control panel for setting important operative parameters

- Designed with aesthetics and ergonomics in mind for best performance

- A state-of-the-art manufacturing facility produces this product

- For optimal operations, world-class items are bought out

- For optimal operations, world-class items are bought out

- The machine is operator-friendly, so it is easy to operate and maintain

- Long-lasting and trouble-free design

Metal Electrical Modular Box Making Machines

Economical Plant

Technical Specifications

| Particulars | Specifications |

| Brand | TL Pathak |

| Product Name | Electrical Modular Box Making Machines |

| Item Code | EM-TL-960 |

| Function | Various operations are performed on sheet metal to produce modular boxes |

| Automation Grade | Automatic / Semi-automatic |

| Application | Housing electrical, mechanical components |

| Raw Material | Galvanized Iron (GI) sheet |

| Man Power Requirement | Up to 5 |

| Production Speed | Up to 1500 pieces / 8-hrs shift |

| Gear Box | Bonfiglioli – Italy or equivalent |

| Box Shape | Rectangular, Square |

| Box Size | Customizable |

| Main Motor | Siemens, Japan or equivalent |

| Mounting Type | Wall Mounting |

| Working Temperature | -10 °C to 40 °C ( 14 °F to 104 °F ) |

| Working Humidity | Up to 90 percentage |

| Ancillary Equipment 1 | Voltage stabilizer |

| Ancillary Equipment 2 | Power generator |

| Switch Gears | Schneider – France or equivalent |

| IP Protection Class | IP54 |

| Power Supply | 440 volts, 50 Hz, AC, three phase with neutral |

| Noise Level | Up to 80 dbA |

| Working Hours | 24 hours per day |

Quality Control

Measures for Machine made Modular Boxes

Quality control measures for machine-made modular boxes play a crucial role in ensuring the products meet industry standards and customer expectations. Regular inspections during the manufacturing process help identify any defects or deviations from specifications early on. This proactive approach allows for immediate corrective actions to be taken, reducing the chances of faulty products reaching the market.

Utilizing advanced technologies such as automated quality testing equipment can enhance accuracy and efficiency in identifying any issues with the modular boxes. These machines can conduct precise measurements and tests that may be challenging to perform manually.

Implementing stringent guidelines and protocols for quality assurance helps maintain consistency in product quality across batches. This ensures that every machine-made modular box meets the required safety and performance standards before being released to consumers. Continuous training programs for production staff on quality control procedures can improve awareness and adherence to established protocols, further enhancing overall product quality. By emphasizing the importance of quality at every stage of manufacturing, companies can build a reputation for reliability and excellence in their products.

Future of Machine-made Metal Electrical Modular Boxes

As technology continues to advance at a rapid pace, the future of machine-made metal electrical modular boxes looks promising. Manufacturers are constantly investing in research and development to improve efficiency and quality. With the integration of AI and automation, machines will be able to produce modular boxes with even greater precision and speed. This means faster turnaround times for customers without compromising on durability or safety standards.

Furthermore, advancements in materials science will allow for the creation of lighter yet stronger metal alloys, making the modular boxes more durable while reducing overall weight. This not only benefits installation processes but also minimizes transportation costs.

High-tech infrastructure and advanced technology used in manufacturing process

With a team of skilled engineers and technicians, TL Pathak leverages the latest technological advancements to design and produce high-quality modular box making machines that meet industry standards. From CAD/CAM software for design to CNC machining for fabrication, every aspect of production is meticulously planned and executed using innovative techniques.The use of high-tech infrastructure not only enhances the quality of the machines but also increases productivity, allowing TL Pathak to cater to a wide range of customer needs efficiently. By investing in advanced technology, TL Pathak stays ahead in the market by offering reliable and durable electrical modular box making machines tailored to meet specific requirements.

The application of

electrical modular box making machines

2 Module

3 Module

4 Module

6 Module

8 Module(H)

8 Module(V)

12 Module

16 Module

18 Module

Choose TL Pathak for your machinery needs and experience

excellence in every aspect of your purchase

TL Pathak stands out as the top choice for electrical modular box making machines in India, thanks to their unparalleled expertise and commitment to quality. With a focus on customer satisfaction, TL Pathak ensures that every machine delivered meets the highest standards of performance and durability.

Their machines are equipped with cutting-edge technology and boast features that set them apart from other manufacturers in the market. The success stories and testimonials from satisfied customers speak volumes about the reliability and efficiency of TL Pathak's products.

Moreover, TL Pathak's after-sales service provides peace of mind to customers, knowing that they have support every step of the way. When it comes to manufacturing high-quality electrical modular box making machines, TL Pathak is a name you can trust.