Cable Tray Making Machine

Cable Tray Making Machines

Revolutionize Your Cable Tray Production with TL Pathak's Leading Manufacturing Technology

Economical Plant

How TL Pathak's Manufacturing Technology is

Revolutionizing Cable Tray Production

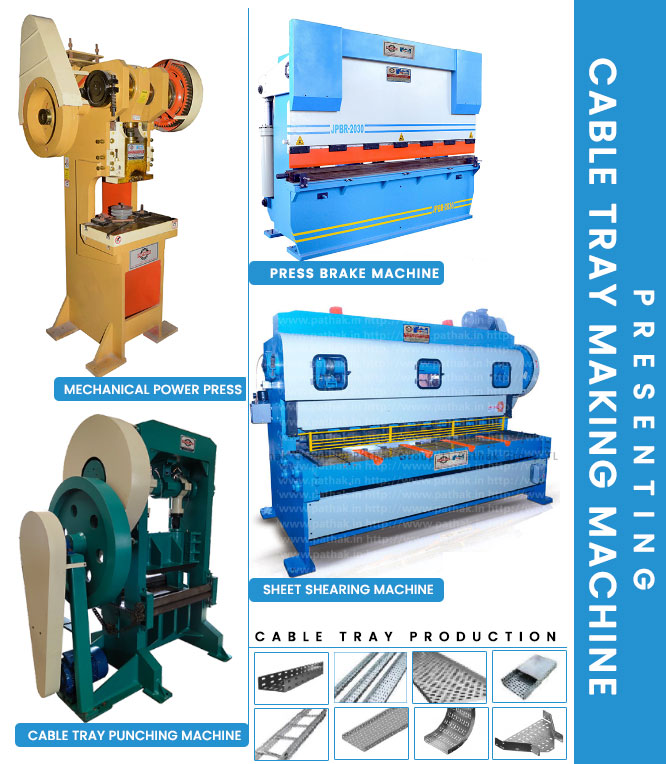

At TL Pathak, we take immense pride in our reputation as the foremost manufacturers of Cable Tray Making Machine. Our state-of-the-art facilities are equipped with cutting-edge technology such as Sheet Shearing Machine, Cable Tray Punching Machine, Mechanical Power Press, and Hydraulic Press Brake, ensuring that each machine we produce is of the highest quality and precision. With years of experience and expertise in the industry, our team of skilled engineers and technicians work tirelessly to innovate and improve upon our designs to meet the ever-evolving needs of our customers. When you choose TL Pathak for your cable tray making needs, rest assured that you are investing in a product that is built to last and exceed expectations.

In the world of manufacturing, technology is constantly evolving and revolutionizing traditional processes. One company leading the charge in this transformation is TL Pathak, whose innovative manufacturing technology is changing the game for cable tray production. In the realm of manufacturing technology, innovation is the key to unlocking new possibilities. One such trailblazer in the industry is TL Pathak and their cutting-edge advancements in cable tray production.

The traditional process of cable tray production

In the past, cable tray production relied heavily on manual labor and outdated machinery. Workers would have to measure and cut metal sheets by hand, leading to inconsistencies in size and shape. The punching of holes for cable entry points was a time-consuming process that often resulted in imprecise outcomes.

Traditional methods also involved bending and shaping the metal sheets using mechanical power presses or hydraulic press brakes. This required skilled operators to ensure accuracy, but even then, there were limitations in achieving complex designs efficiently. Assembly of the cable trays was another labor-intensive task, requiring welding or screwing components together manually. This not only added to production time but also increased the risk of errors in the final product.

Overall, the traditional process of cable tray production was slow, prone to errors, and lacked efficiency compared to modern manufacturing technologies like those offered by TL Pathak's innovative solutions.

How TL Pathak's technology is changing the game

TL Pathak's innovative manufacturing technology is revolutionizing the cable tray production industry. By incorporating cutting-edge machinery such as Sheet Shearing Machines, Cable Tray Punching Machines, Mechanical Power Presses, and Hydraulic Press Brakes into their processes, they have set a new standard of efficiency and precision. Gone are the days of labor-intensive manual work that is prone to errors and delays. TL Pathak's technology streamlines production processes, significantly reducing lead times while maintaining exceptional quality standards. The combination of automation and advanced equipment ensures consistent output with minimal margin for error. With TL Pathak's technology at the helm, businesses can now meet market demands quicker without compromising on product quality. This not only enhances operational efficiency but also boosts overall productivity and profitability in the long run.

Cable Tray Making Machine

Economical Plant Features

- For long life and precise pressing of materials, die sets are manufactured with high quality materials.

- Heavy-duty frames and reinforced structures are typically used in presses to withstand pressures and forces, ensuring long-term stability and reliability.

- Durable components and reliable performance ensure consistent production and minimize downtime.

- Reduces energy consumption by using energy-efficient technologies, such as motor controls or power-saving features.

- An easy-to-use control panel for setting important operative parameters.

- Best performance from an aesthetic and ergonomically designed machine.

- A state-of-the-art manufacturing facility produces this product.

- For optimal operations, we bought out world-class items.

- Designed to work 24 hours a day, 7 days a week.

- Easy-to-operate and easy-to-maintain machine.

- Long-lasting and trouble-free design.

Technical Specifications

| Particulars | Specifications |

| Brand | TL Pathak |

| Product Name | Cable Tray Making Machines |

| Item Code | CT-TL-962 |

| Function | Various operations are performed to produce cable trays from metal sheet |

| Production Speed | Up to 1.25 meter / minute |

| Raw Material | Metal sheet strips |

| Sheet Thickness | Up to 2 mm (Approx) |

| Sheet Width | Up to 750 mm (Approx) |

| Application | In commercial, industrial, and residential settings, for organizing and supporting electrical and data cables. |

| Main Motor | Siemens, Japan or equivalent |

| Gear Box | Bonfiglioli – Italy or equivalent |

| Switch Gears | Schneider – France or equivalent |

| Power Supply | 440 Volts, 50 Hz, A.C., Three phase with neutral (can also be designed as per specific requirement) |

Advantages and benefits of using

TL Pathak's manufacturing technology

TL Pathak's manufacturing technology offers a myriad of advantages and benefits that are revolutionizing the cable tray production industry. With cutting-edge Sheet Shearing Machines, Cable Tray Punching Machines, Mechanical Power Presses, and Hydraulic Press Brakes, TL Pathak is setting new standards for efficiency and precision. One key advantage of using TL Pathak's technology is the significant increase in productivity it provides. The automated processes streamline production timelines and reduce manual labor requirements, leading to faster turnaround times for clients. Additionally, the high level of accuracy achieved with these machines ensures consistent quality in every cable tray produced.

Moreover, TL Pathak's technology promotes cost-effectiveness by minimizing material waste and optimizing resource utilization. This not only reduces operational expenses but also enhances sustainability efforts within manufacturing facilities. By investing in TL Pathak's innovative solutions, businesses can stay ahead of the competition while delivering superior products to their customers.

The future of cable tray production with TL Pathak

As technology continues to advance at a rapid pace, the future of cable tray production with TL Pathak looks brighter than ever. With their cutting-edge manufacturing technology, they are paving the way for more efficient and precise production processes.TL Pathak's innovative Sheet Shearing Machine, Cable Tray Punching Machine, Mechanical Power Press, Hydraulic Press Brake have revolutionized the industry by offering faster turnaround times and higher quality products. This not only benefits manufacturers but also end-users who rely on these cable trays for various applications.

By investing in TL Pathak's technology, businesses can stay ahead of the competition and meet growing demands in the market. The flexibility and customization options provided by their machines ensure that companies can adapt to changing requirements seamlessly. With TL Pathak leading the charge in manufacturing technology for cable trays, we can expect to see even more advancements that will further streamline production processes and enhance product quality.

The application of

electrical modular box making machines

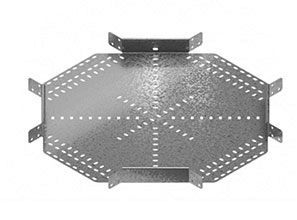

Cable Tray Design

Cable Tray Design

Cable Tray Design

Cable Tray Design

Cable Tray Design

Cable Tray Design

Cable Tray Design

Cable Tray Design

Investing in the right

manufacturing technology for your business

Investing in the right manufacturing technology for your business is crucial to staying competitive and efficient in today's fast-paced industry. TL Pathak's revolutionary manufacturing technology, including the Sheet Shearing Machine, Cable Tray Punching Machine, Mechanical Power Press, and Hydraulic Press Brake, has been transforming cable tray production processes. By adopting TL Pathak's cutting-edge technology, businesses can streamline their operations, increase productivity, reduce costs, and improve overall quality. The advantages and benefits of using TL Pathak's machinery are evident through the testimonials of satisfied clients who have experienced firsthand the positive impact on their production processes.

As we look towards the future of cable tray production with TL Pathak at the helm, it is clear that innovation will continue to drive progress in this sector. Embracing advanced manufacturing technologies will be essential for companies looking to stay ahead of the curve and meet evolving industry demands.Choosing TL Pathak's Manufacturing Technology means investing in efficiency, quality, and success for your business. Stay ahead of the competition by embracing cutting-edge machinery that revolutionizes cable tray production processes.