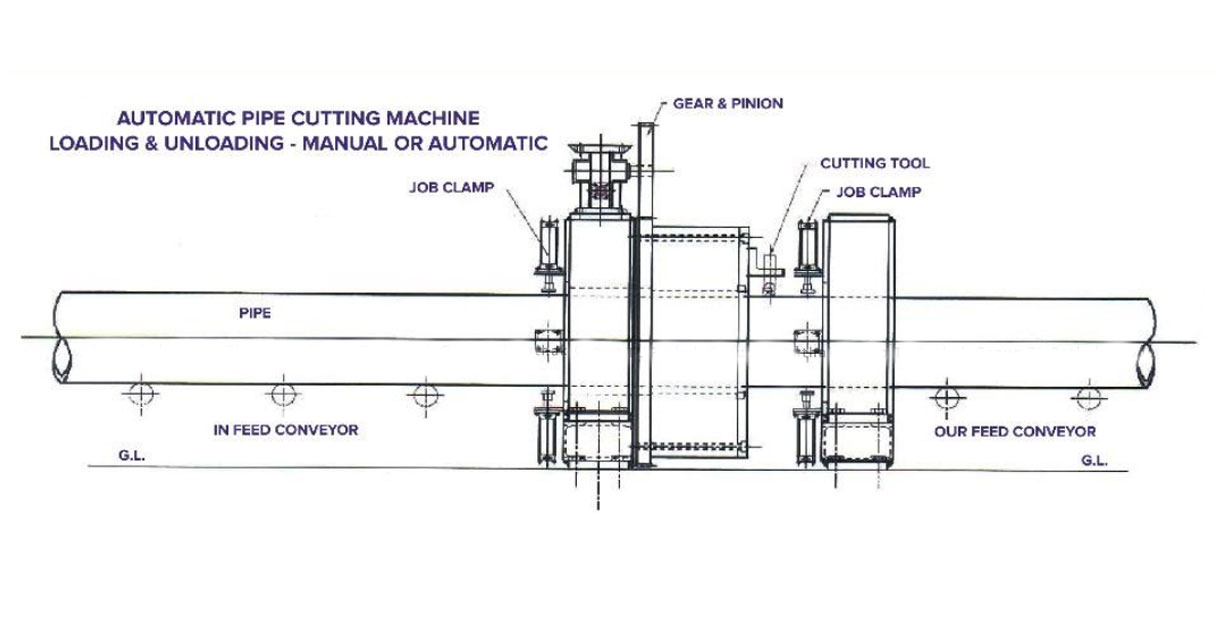

Automatic Pipe Cutting Machine Loading & Uploading Manual or Automatic

Idler MachineAutomatic Pipe Cutting Machine is available in two version. In the simpler version. the pipe is placed on to the roller of in feed conveyor and is pushed manually till it touches the stopper. The Start button is pressed which clamps the idler pipe and a cutting tool moves round the pipe to complete the parting operation and the pipe is uploaded manually.In the advanced version, the pipes are placed on the rack from where it is loaded one by one to the infeed conveyor, which conveys the pipes to the cutting station for parting the pipes to the predetermined length and is unloaded from the outfeed conveyor.

Idler Testing Equipment is supplied for testing of the idler after assembly. Dust proof testing is done in a chamber where the idler is rotated by a motor and in an artificially created dirty atmosphere for predetermined time after which it is taken out for inspection. In case of Water Proof Testing, the idler is rotated in a closed chamber and water is poured with inspection. For Radial Run out Test, a stand with steady rest is supplied for mounting of the idler and rotation by hand and a dial gauge indicated the run out. Test, a stand with steady rest is supplied for mounting of the idler and roation by hand and a dial gauge indicated the run out. For measuring the Friction Factor, the idler is rotated at predetermined speed by pressure of a rubberized roller which is taken away and the idler under testing is allowed to rotate of its own & digital meters indicate the RPM & time it takes to come to the rest. The data is used to determine Friction Factor

Download Catalog Request Catalog

Order By Phone

Shipping Information Usually dispatched With In business days

+91-9124009247 OR Call Me Back