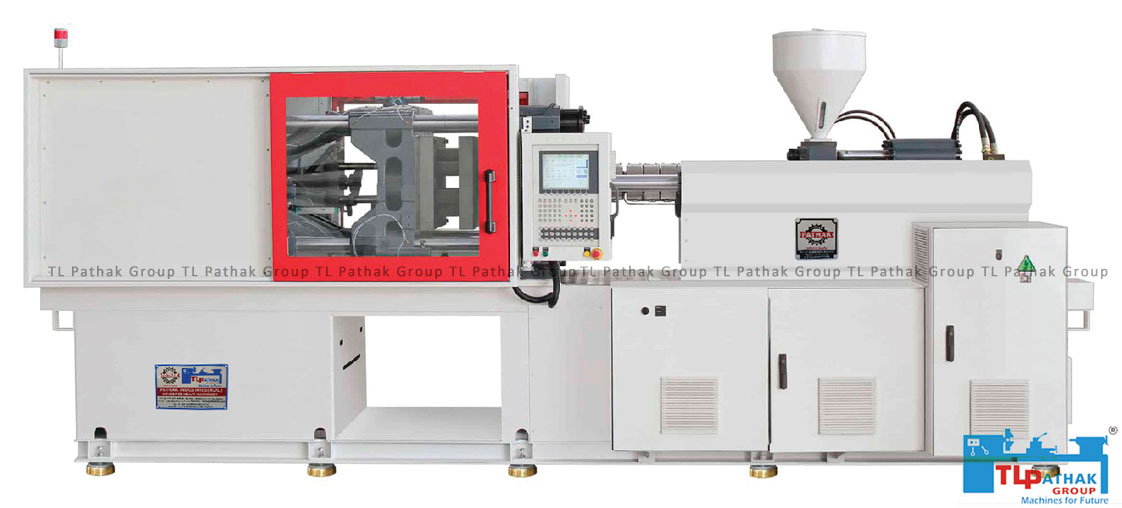

Horizontal Injection Moulding Machine

Plastic Making MachineHorizontal injection moulding has long been the most popular style of injection moulding. The mould opens and closes along a horizontal axis in horizontal injection moulding to fill the mould cavities that provide adequate packing, cooling and accurate injection pressure. Furthermore, because the mould halves are separated horizontally, portions from these moulds spontaneously fall out of the cavity after injection and do not need to be manually retrieved.

Download Catalog Request Catalog

Order By Phone

Shipping Information Usually dispatched With In business days

+91-9124009247 OR Call Me Back| INJECTION UNIT | TOP PP | 85 | 100 | 130 | 170 | 220 | 260 | 290 | 350 | 400 | 450 | 550 | 650 | 750 |

| Screw Diameter | MM | 35 | 38 | 42 | 45 | 50 | 55 | 60 | 70 | 75 | 80 | 85 | 90 | 95 |

| Screw L/D Ratio | - | 19 | 20.3 | 22 | 22 | 22 | 22 | 22 | 20 | 20 | 20 | 21.1 | 21 | 22 |

| Shot size (Theroretical) | CM3 | 160 | 193.2 | 277 | 357 | 490 | 704 | 805 | 1226 | 1520 | 1910 | 2468 | 2582 | 3195 |

| Injection Weight (PS) | CMS | 146 | 176 | 252 | 325 | 446 | 641 | 733 | 1226 | 1383 | 1738 | 2246 | 2350 | 2907 |

| Injection Pressure | MPA | 170 | 184 | 171 | 177 | 168 | 170 | 170 | 168 | 173 | 172 | 167 | 164 | 175 |

| Screw Speed | R/MIN | 225 | 210 | 185 | 180 | 155 | 220 | 220 | 160 | 160 | 155 | 150 | 125 | 130 |

| CLAMPING UNIT | ||||||||||||||

| Toggle Stroke | MM | 320 | 350 | 380 | 435 | 475 | 540 | 590 | 670 | 710 | 760 | 900 | 930 | 1000 |

| Clamp Tonnage | KN | 850 | 1000 | 1300 | 1700 | 2200 | 2600 | 2900 | 3500 | 4000 | 4500 | 5500 | 6500 | 7500 |

| Tia Bar Diameter | MM | 60 | 65 | 70 | 80 | 90 | 95 | 100 | 110 | 120 | 130 | 150 | 160 | 165 |

| Space Between Tia Bar | MM | 360x 340 |

370x 370 |

420x 420 |

470x 470 |

520x 520 |

570x 570 |

620x 620 |

710x 630 |

760x 670 |

800x 720 |

900x 820 |

960x 880 |

1000x 940 |

| Max.Mold Height | MM | 350 | 380 | 450 | 520 | 560 | 600 | 630 | 710 | 780 | 800 | 850 | 900 | 1000 |

| Min Mold Height | MM | 150 | 150 | 160 | 180 | 200 | 200 | 200 | 260 | 250 | 300 | 350 | 350 | 400 |

| Ejector Stroke | MM | 90 | 120 | 140 | 140 | 150 | 150 | 150 | 200 | 200 | 200 | 250 | 260 | 300 |

| Ejector Tonnage | KN | 30 | 38 | 50 | 50 | 70 | 70 | 70 | 90 | 110 | 110 | 250 | 200 | 200 |

| OTHERS | ||||||||||||||

| Max.Pump Pressure | MPA | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Electric Motor | KW | 11 | 13 | 13 | 18.5 | 18.5 | 30 | 30 | 37 | 37 | 45 | 55 | 30+30 | 30+37 |

| Heater Power | KW | 6.5 | 7.5 | 8 | 12.5 | 14 | 19 | 19 | 24.5 | 26 | 34 | 36 | 37.2 | 49 |

| Machine Dimension (LxWxH) | M | 3.9 x 1.2 x 1.8 |

4.3 x 1.3 x 2.0 |

4.6 x 1.5 x 2.1 |

5.1 x 1.5 x 2.2 |

5.7 x 1.6 x 2.3 |

6.2 x 1.5 x 2.2 |

6.3 x 1.7 x 2.4 |

7.3 x 1.8 x 2.2 |

7.3 x 1.8 x 2.2 |

7.6 x 1.96 x 2.41 |

9.3 x 2.1 x 2.4 |

9.6 x 2.4 x 2.7 |

1.6 x 2.6 x 2.8 |

| Machine Weight | T | 2.8 | 3.4 | 4 | 6 | 7 | 8.3 | 9.3 | 12.5 | 14.2 | 18.8 | 23 | 32 | 39 |

Moulding Machine Application 1

Moulding Machine Application 2

Moulding Machine Application 3

Moulding Machine Application 4