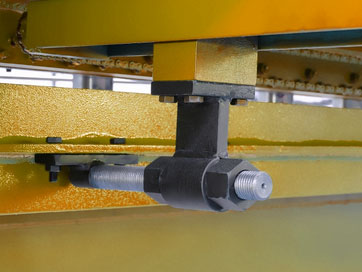

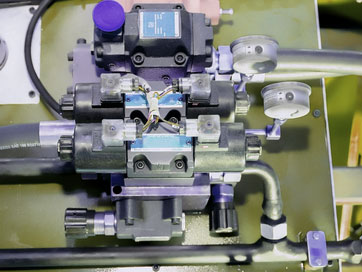

NC Shearing Machine

Sheet Metal MachinesTL Pathak Group's NC Shearing Machine stands as a pinnacle of precision and efficiency in sheet metal cutting. Engineered with cutting-edge Numerical Control (NC) technology, this machine ensures unparalleled accuracy and repeatability in the shearing process. Its programmable controls enable the customization of cutting parameters, accommodating a diverse range of sheet metal sizes and thicknesses with ease. The robust construction and advanced features of TL Pathak Group's NC Shearing Machine make it an indispensable tool in metal fabrication, automotive manufacturing, aerospace, and various other industries.

Whether it's producing components for machinery, automotive parts, or structural elements for construction, this machine delivers consistent, high-quality results. The user-friendly interface enhances operational efficiency, allowing operators to execute complex cutting tasks with precision. TL Pathak Group's NC Shearing Machine sets a new standard for reliability and performance in the realm of sheet metal cutting technology.

Download Catalog Request Catalog

Order By Phone

Shipping Information Usually dispatched With In business days

+91-9124009247 OR Call Me Back

Metal Fabrication Shops

Automotive Industry

Aerospace Industry

Construction

General Sheet Metal Cutting

Appliance Manufacturing