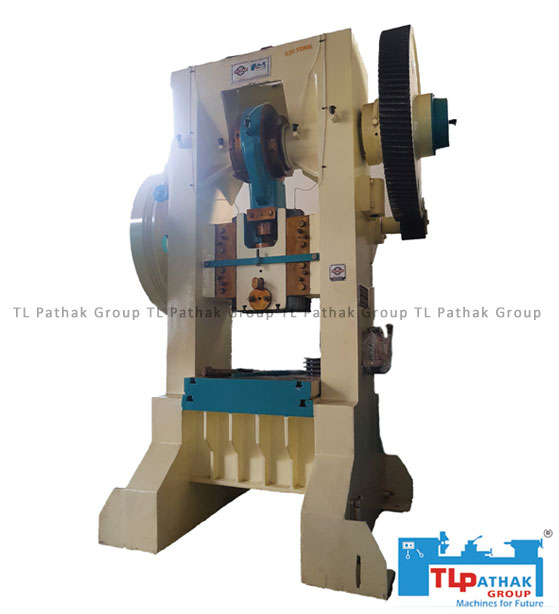

Pillar Type H Type Power Press

Press MachinesOur engineers manufacture high-quality Pillar Type H Type Power Press mainly used in shear, punch, form, or assemble metal or other material using tools or die attached to slides and essential equipment for many industries and mainly used in automobile, aeronautical and spacecraft industries. It is made with the latest technology, and all features needed by the customer are available on it.

Pillar Type H Type Power Press 150 Ton Capacity. We are also provide Punch & Die as Per Sample / Drawing

Frame : Made of Mild steel and Fabrication properly. Bearing surface are hand scrapped.

Crank Shaft : Made of special steel stock to withstand the effective load, properly machined, fitted in bushes with high accuracy/

Ram Slide :

Made of Cast Iron with high grade quality, properly seasoned after

rough machining. Bearing surfaces are hand scrapped, with reamed hole

for die clamping

Fly Wheel : Made of high grade cast Iron and is designed to generated the equipment energy.

Brake : The Brake is powerful and work on the top dead enter and compensated by springs.

Stroke : Presses are manufactured with adjustable stroke and adjustments can be made by means of a worm.

Clutch

: The Clutch is very rigid, better supported and less liable to suffer

damage under heavy operating conditions. The Clutch gives continuous

stroke for mass production.

Rolling Key : The key is "double key rolling type" made out of special alloy steel of EN series.

Lubrication : An efficient lubrication system can be provided to lubricate the sliding surfaces and moving parts at extra cost.

Ejector & Double Key System : These can be provided specially for he use of springs dies agint extra cost.

Download Catalog Request Catalog

Order By Phone

Shipping Information Usually dispatched With In business days

+91-9124009247 OR Call Me BackModel |

PP3 30 Tons |

PP5 50 Tons |

PP7 75 Tons |

PP10 100 Tons |

PP15 |

PP20 200 Tons |

PP25 250 Tons |

|

| Dia of Crank Shaft | mm | 100 | 115 | 125 | 150 | 175 | 200 | 225 |

| Adjustability of Stroke | mm | 76 | 100 | 100 | 125 | 150 | 150 | 150 |

| Punch Bore in Ram | mm | 31 | 38 | 38 | 45 | 50 | 50 | 57 |

| Width of Bed | mm | 450 | 500 | 600 | 700 | 750 | 800 | 900 |

| Length of Bed | mm | 450 | 500 | 600 | 700 | 750 | 800 | 900 |

| Gear Dia | mm | 600 | 650 | 890 | 960 | 1060 | 1125 | 1200 |

| Fly Wheel Dia | mm | 700 | 800 | 900 | 1000 | 1125 | 1200 | 1275 |

| Gap (Bed to Bottom ) | mm | 350 | 375 | 400 | 450 | 500 | 550 | 600 |

| Stroke per Minute | mm | 60 | 45 | 40 | 40 | 35 | 35 | 35 |

| H.P. Required (1440) | mm | 3 | 5 | 7.5 | 10 | 15 | 20 | 25 |

| Bore in Bed | mm | 140 | 160 | 190 | 220 | 250 | 275 | 290 |

| Weight in kgs (Approx) | mm | 1550 | 2050 | 3300 | 4600 | 6000 | 8400 | 10000 |