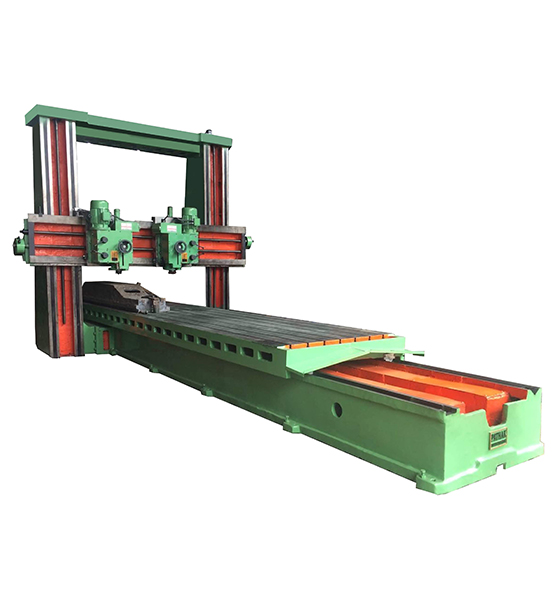

Plano Milling Machine

Workshop EquipmentsThe Plano Milling Machine by TL Pathak Group in India is a high-performance tool used for machining large and heavy workpieces with precision. This machine features a robust gantry design and powerful milling heads, enabling efficient material removal and surface milling. It offers a generous worktable size and adjustable milling speeds, providing versatility for various machining tasks. The Plano Milling Machine is ideal for industries such as aerospace, automotive, and heavy machinery manufacturing, where accuracy and reliability are crucial for achieving superior machining results.

Download Catalog Request Catalog

Order By Phone

Shipping Information Usually dispatched With In business days

+91-9124009247 OR Call Me Back

Step less table feeds & rapid system

Speed range covers both carbide & H.S.S. tools

Fixed or swivel head up to 45

Suitable for milling,Drilling,Facing Boring & Grinding

Safety cluthes for electrical & mechanical interlocking is provided for

Preventing trouble due to faulty operation

Automatic lifting & lowering of cross rail

Forced lubrication for guideways & gearboxes

Rapid operation to cross traverse of the milling head

Extra Milling Head on Cross Rail

Boring Head on Either of Side Columns

Grinding Head On Cross Rail

Automatic Locking of the Cross Rail

Extra milling head on either or both the columns

Bellow covers to the guideways

Optical read out

Right angle milling attachment

Digital Read Out

| MODEL | 1218/1225/1235 | 1625/1635/1645 | 2035/2045/2060 |

| Table Size (mm) | 800 x 2100/2800/3800 | 950 x 2800/3800/4800 | 1300 x 3800/4800/6300 |

| Table Stroke (mm) | 1800/2500/3500 | 2500/3500/4500 | 3500/4500/6000 |

| No. of T - Slots | 5 | 6 | 8 |

| Width of T - Slots (mm) | 20 | 20 | 20 |

| Distance Between T -Slots (mm) | 145 | 150 | 150 |

| Table Feed Stepless (mm/min) | 40-600 | 40-600 | 40-600 |

| Table Rapid Stepless (mm/min) | 3000 | 3000 | 3000 |

| Table Feed Motor (hp) | 2/3/3 | 3/5/5 | 5/7.5/7.5 |

| Width Between Column (mm) | 1200 | 1600 | 2000 |

Maximum Height under Spindle (mm) |

1000 | 1000 | 1000 |

| Vertical Traverse of cross Rail (mm) | 1030 | 1030 | 1030 |

| Vertical Feed of Cross Rail (mm/min) | 300 | 300 | 300 |

| Cross Rail Feed Motor (hp) | 3 | 3 | 3 |

| Horizontal Traverse of one Saddle (mm) | 1700 | 2100 | 2500 |

| Saddle Cross Feed Motor (hp) | 3 | 3 | 3 |

| Saddle Cross Feed Stepless (mm/min) | 40-600 | 40-600 | 40-600 |

| Saddle Cross Rapid Stepless (mm/min) | 2200 | 2200 | 2200 |

| Milling Head | |||

| RPM | 80-500 | 80-500 | 80-500 |

| Speeds | Variable (2 step) | Variable (2 step)/div> | Variable (2 step) |

| Motor (hp) | 5 | 5 | 5 |

| Spindle Nose | 150-50 | 150-50 | 150-50 |

| Quill Traverse (manual) (mm) | 100 | 100 | 100 |

| Maximum Cutter Die (mm) | 125/160 | 125/160 | 125/160 |

| Swivel (manual) | .45'' | .45'' | .45'' |

| Standard | - | (standard machine comes with one vertical head) | - |

| Optional | - | Up to four (Two on cross slide ) (Two , One each on Both Columns ) | - |

| Overall Size ( L x B x H) | 2700/3750/5250 x 3035 x 2900 | 3750/5250/6750 x 3435 x 2900 | 5250/6750/9000 x 3835 x 2900 |