HDPE - Pipe Jointing Machine Manufacturer in India

What is HDPE - Pipe Jointing Machine ?

HDPE pipe jointing machines are specialized equipment used to join or fuse High-Density Polyethylene (HDPE) pipes. These machines ensure strong and reliable connections between HDPE pipes in various applications. The type of machine used depends on the specific jointing method, such as butt fusion, electrofusion, or socket fusion.

Butt fusion machines heat the pipe ends and apply pressure to fuse them together, commonly used for large diameter pipes. Electrofusion machines utilize electrical current to heat and fuse electrofusion fittings with the pipe ends. Socket fusion machines heat the pipe and socket, which are then joined under pressure.

These machines provide controlled heating, pressure, and fusion processes. Proper calibration, temperature control, and pressure application are crucial for achieving high-quality joints. Following manufacturer instructions and safety guidelines, as well as regular maintenance, ensures optimal performance of the machines.

HDPE pipe jointing machines play a vital role in creating secure, leak-proof joints, contributing to the durability and reliability of HDPE pipe systems.

Types Of HDPE - Pipe Jointing Machine -

There are different types of HDPE pipe jointing machines available in the market, each designed for specific jointing methods. Here are the common types of HDPE pipe jointing machines:

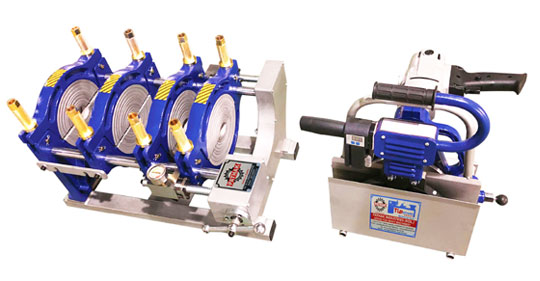

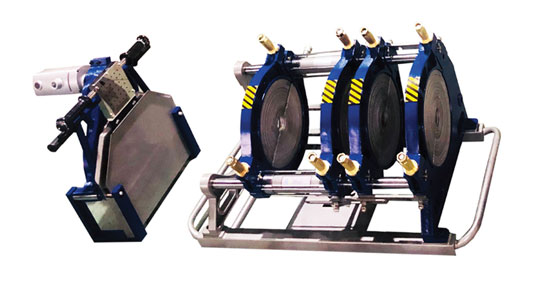

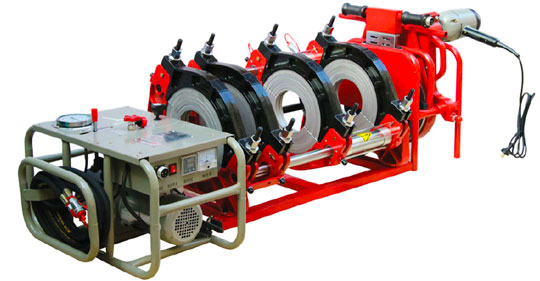

1. Butt Fusion Machines: Butt fusion machines are used for joining HDPE pipes using the butt fusion method. They typically consist of a heating element or plate and a hydraulic system. Butt fusion machines come in various sizes to accommodate different pipe diameters, ranging from small handheld machines for smaller pipes to larger machines for larger diameter pipes.

2. Electrofusion Machines: Electrofusion machines are used for electrofusion jointing of HDPE pipes. These machines include a control unit and are specifically designed to facilitate the electrofusion process. They provide precise control over the electrical current and fusion parameters to ensure a reliable joint.

3. Socket Fusion Machines: Socket fusion machines are used for socket fusion jointing of HDPE pipes. These machines heat the pipe and socket using a heating tool or plate. Socket fusion machines come in different sizes to accommodate various pipe diameters and socket sizes.

4. Hydraulically Operated Fusion Machines: Hydraulically operated fusion machines are used in conjunction with butt fusion machines to provide the necessary pressure during fusion. These machines supply hydraulic pressure to the fusion machine's hydraulic system, ensuring a secure and consistent fusion of the HDPE pipes.

5. Manual Fusion Machines: Manual fusion machines are typically used for smaller diameter pipes and low-volume applications. They are simple in design and operation, relying on manual pressure application to create the fusion between the pipe ends.

It's important to note that the availability and specific types of HDPE pipe jointing machines may vary based on the manufacturer and the region. Additionally, each type of machine may come with different features, such as digital controls, data logging capabilities, and automated processes, to enhance the efficiency and accuracy of the jointing process.

Advantage Of HDPE - Pipe Jointing Machine :

HDPE pipe jointing machines offer several advantages for the jointing or fusion of High-Density Polyethylene (HDPE) pipes. Here are some key advantages of using HDPE pipe jointing machines:

1. Efficient and Precise Fusion: HDPE pipe jointing machines provide controlled heating and pressure application, ensuring efficient and precise fusion of HDPE pipes. This results in strong and reliable joints that are resistant to leaks and provide long-term durability.

2. Time and Cost Savings: By using HDPE pipe jointing machines, the fusion process can be completed quickly and efficiently. This helps save time during installation or repair projects, reducing labor costs and improving overall project timelines.

3. Consistent Fusion Quality: HDPE pipe jointing machines are designed to maintain consistent fusion quality throughout the jointing process. They ensure uniform heating, proper pressure application, and fusion parameters, resulting in reliable joints with consistent strength and integrity.

4. Enhanced Safety: These machines are equipped with safety features to protect operators during the jointing process. They include measures such as automatic shutdown mechanisms, temperature control systems, and safety interlocks, minimizing the risk of accidents or injuries.

5. Versatility: HDPE pipe jointing machines are available in various sizes and types to accommodate different pipe diameters and jointing methods. This versatility allows for the fusion of a wide range of HDPE pipes, catering to diverse project requirements.

6. Improved Joint Longevity: Proper fusion using HDPE pipe jointing machines creates joints that are highly resistant to leaks, corrosion, and other environmental factors. This helps extend the lifespan of the HDPE pipe system, reducing maintenance and replacement costs over time.

7. Quality Assurance and Compliance: The use of HDPE pipe jointing machines ensures adherence to industry standards and specifications for HDPE pipe jointing. This helps guarantee the quality and integrity of the joints, ensuring compliance with regulatory requirements.

It's important to note that the advantages of HDPE pipe jointing machines can vary depending on the specific machine model, manufacturer, and jointing method employed. Proper training, maintenance, and adherence to manufacturer guidelines are essential for maximizing the benefits and performance of these machines.

Use of HDPE pipe jointing machines :

HDPE pipe jointing machines are utilized in various applications that involve the installation, repair, or maintenance of High-Density Polyethylene (HDPE) pipes. Here are some common uses of HDPE pipe jointing machines:

1. Infrastructure Projects: HDPE pipes are widely used in infrastructure projects such as water supply systems, sewage and wastewater systems, stormwater drainage systems, and gas distribution networks. HDPE pipe jointing machines are employed during the installation and connection of these pipes, ensuring secure and leak-proof joints.

2. Construction Industry: HDPE pipes find application in the construction industry for various purposes, including underground utility networks, irrigation systems, and geothermal heating systems. HDPE pipe jointing machines play a crucial role in connecting and fusing pipes during construction projects, ensuring reliable and efficient pipe networks.

3. Industrial Applications: Many industrial processes require the use of HDPE pipes, including chemical processing plants, mining operations, and manufacturing facilities. HDPE pipe jointing machines are used to create strong and durable joints in these industrial applications, maintaining the integrity and efficiency of fluid transportation systems.

4. Repair and Maintenance: HDPE pipe jointing machines are also utilized for repair and maintenance tasks. When sections of HDPE pipes need to be replaced or repaired, these machines help in the removal of damaged sections and the fusion of new pipe sections, ensuring a seamless and reliable connection.

5. Landscaping and Agricultural Systems: HDPE pipes are extensively used in landscaping projects, agricultural irrigation systems, and golf course installations. HDPE pipe jointing machines aid in the assembly and jointing of pipes in these applications, enabling efficient water distribution and ensuring the longevity of the system.

6. Municipal and Government Projects: Municipalities and government bodies often rely on HDPE pipes for infrastructure projects like road drainage systems, culverts, and sewer systems. HDPE pipe jointing machines are crucial for connecting and joining these pipes, providing a cost-effective and durable solution for public infrastructure.

Overall, HDPE pipe jointing machines are utilized across a wide range of industries and applications where HDPE pipes are employed. They ensure efficient and reliable jointing, helping to create robust and long-lasting pipe systems that can withstand various environmental and operational conditions.